Spreadability of powders for additive manufacturing: A critical review of metrics and characterisation methods (Open Access)

• A holistic approach to spreadability characterisation is reviewed.

• Spreadability lacks a universal agreed definition and requires further development.

• Powder properties and process parameters in AM are investigated in parallel.

• Understanding of spreadability characterisation for AM process control is facilitated.

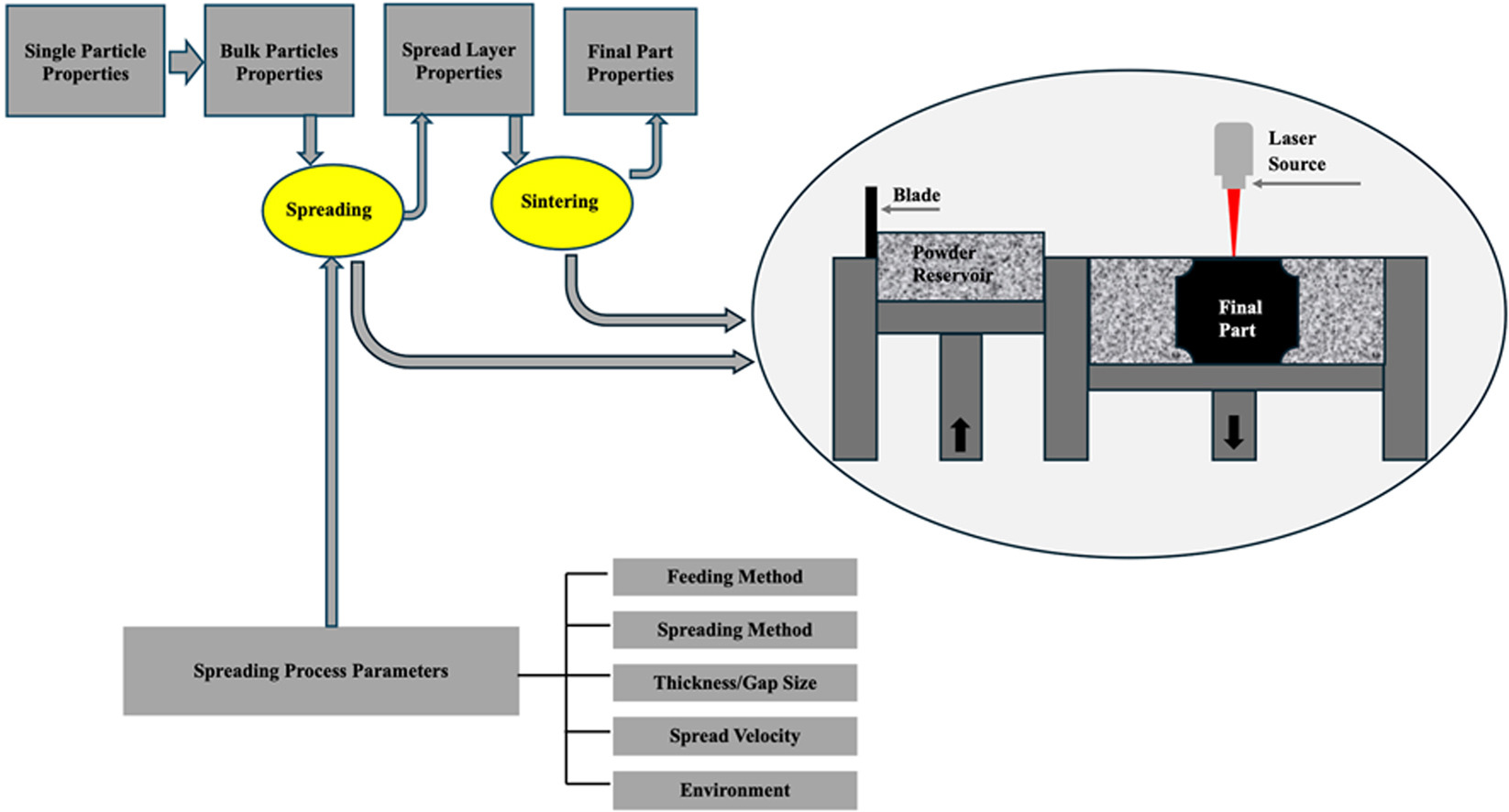

Powder bed fusion methods of additive manufacturing (AM) require consistent, reproducible, and uniform layers of powder for the reliable production of high-quality parts, where properties of powder are central to achieving this. Among these properties, powder flowability and spreadability play critical roles in determining the quality of these powder layers.

While extensive research has been conducted on powder flow and spreading behaviour, and on their characterisation, there is little critical comparison and review of these terms in the context of AM. Such a review is necessary to further develop and enhance our comprehension of spreading dynamics and its relation to powder properties in AM systems.

This review paper aims to build a coherent understanding of the correlation between powder characteristics and spreading in powder based additive manufacturing and its impact on manufactured parts. It highlights the current progress in comprehending spreading dynamics, the influence of powder characteristics, environmental conditions, spreading system, and the development of testing tools to assess powder spreadability. Furthermore, the paper critically discusses the challenge of finding appropriate quantitative metrics and recent advances in the use of standardised methods for evaluating powder spreadability.