-

Volumes 84-95 (2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 92

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

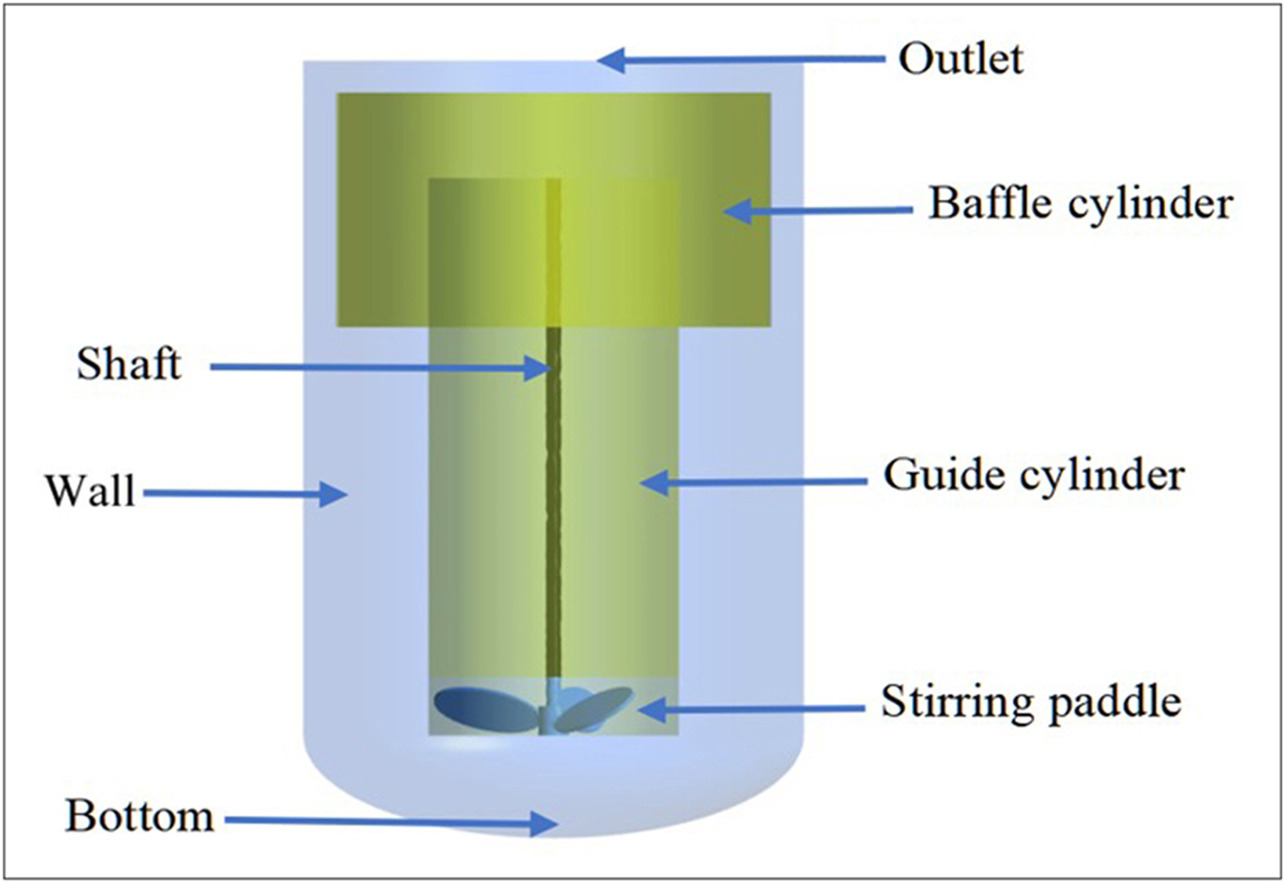

• The Euler-Eulerian and Euler-Lagrangian two-fluid model were used to study the hydrodynamic behavior of DTB crystallizer.

• The theory of particle dynamics was introduced to focus on the distribution of crystals in the DTB crystallizer.

• Leading to an improved prediction of crystal growth , the growth kinetic model was introduced by loading the UDF program.

• Pure liquid phase methanol was taken to simulate the temperature change of the selected DTB during the cooling process.

The suspension state of crystals in the crystallizer is one of the important indicators for evaluating the adaptability of the crystallizer. This study adopted the Euler-Eulerian two-fluid model to simulate and analyze the fluid motion of solid-liquid two-phase flow in the industrial-grade DTB crystallization kettle, as well as the phase suspension distribution of crystal particles. The main influencing factors investigated are: the heat transfer effect, the height of the bottom of the crystallizer, the number and position of the stirring paddle, crystal size and crystal volume fraction. Based on the research of Euler-Eulerian method to simulate fluids, the Euler-Lagrangian method was further used to simulate the motion state of particle phases with different particle sizes in the crystallizer. It was found that the designed DTB crystallizer has good recycle mixing effect. The particles can be mixed evenly during the operation, which can fully realize the solid-liquid mixing and suspension effect of the drug under study.