- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

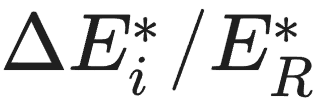

This paper shows that the stiffness of styrene–butadiene solid rubber with added kaolin powder is related to the yield stress of kaolin dispersion in liquid polybutadiene rubber up to the percolation threshold. For five kinds of kaolin powder, the value of τ° spans the range of 100–430 Pa, while the corresponding compressive elastic constant of SBR varies from 12 to 21 MPa. A relationship between τ° and is  proposed. Critical examination of these data infers that kaolin powder dispersed in solid rubber matrix acts as an additive which decreases the random movement of the polybutadiene chains. Consequently, dispersions of nano-particles in liquid and in solid SBR are considered to be related, thus leading to a rheological method for selecting nano-particles as fillers in solid SBR.

proposed. Critical examination of these data infers that kaolin powder dispersed in solid rubber matrix acts as an additive which decreases the random movement of the polybutadiene chains. Consequently, dispersions of nano-particles in liquid and in solid SBR are considered to be related, thus leading to a rheological method for selecting nano-particles as fillers in solid SBR.