- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

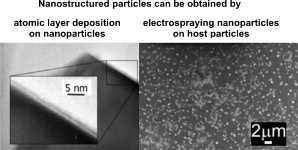

The properties of nanoparticles are often different from those of larger grains of the same solid material because of their very large specific surface area. This enables many novel applications, but properties such as agglomeration can also hinder their potential use. By creating nanostructured particles one can take optimum benefit from the desired properties while minimizing the adverse effects. We aim at developing high-precision routes for scalable production of nanostructured particles. Two gas-phase synthesis routes are explored. The first one – covering nanoparticles with a continuous layer – is carried out using atomic layer deposition in a fluidized bed. Through fluidization, the full surface area of the nanoparticles becomes available. With this process, particles can be coated with an ultra-thin film of constant and well-tunable thickness. For the second route – attaching nanoparticles to larger particles – a novel approach using electrostatic forces is demonstrated. The micron-sized particles are charged with one polarity using tribocharging. Using electrospraying, a spray of charged nanoparticles with opposite polarity is generated. Their charge prevents agglomeration, while it enhances efficient deposition at the surface of the host particle. While the proposed processes offer good potential for scale-up, further work is needed to realize large-scale processes.