- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

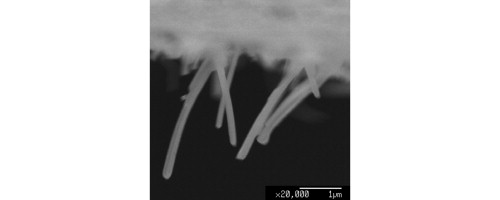

TiO2 nanorods have been successfully grown into a track-etched polycarbonate (PC) membrane by a particulate sol-electrophoretic deposition from an aqueous medium. The prepared sols had a narrow particle size distribution around 17 nm and excellent stability against aging, with zeta potentials in the range of 47–50 mV at pH2. It was found that TiO2 nanorods were grown from dilute aqueous sol with a low, 0.1-M concentration. Fourier transform infrared spectroscopy (FT-IR) analysis confirmed that a full conversion of titanium isopropoxide was obtained by hydrolysis, resulting in the formation of TiO2 particles. X-ray diffraction (XRD) results revealed that TiO2 nanorods dried at 100 °C were a mixture of anatase and brookite phases, whereas they were a mixture of anatase and rutile structures at 500 °C. Moreover, the rutile content of the TiO2 nanorods was higher than that of TiO2 powders. Transmission electron microscope (TEM) images confirmed that TiO2 nanorods had a smooth morphology and longitudinal uniformity in diameter. Field emission scanning electron microscope (FE-SEM) images showed that TiO2 nanorods grown by sol-electrophoresis from the dilute aqueous sol had a dense structure with a uniform diameter of 200 nm, containing small particles with an average size of 15 nm. Simultaneous differential thermal (SDT) analysis verified that individual TiO2 nanorods, grown into a PC template, were obtained after annealing at 500 °C. Based on kinetic studies, it was found that uniform TiO2 nanorods with high-quality morphology were obtained under optimum conditions at an applied potential of 0.3 V/cm and a deposition time of 60 min.