- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

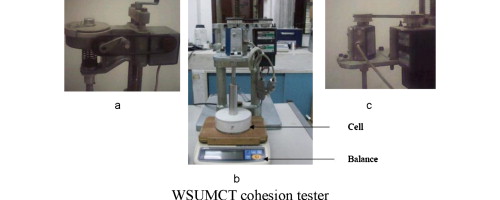

The measurement of powder flowability is a major concern for most industrial processes that deal with the handling of bulk solids as raw materials, intermediates, or products. The development of devices that measure the flowability of non-aerated powders has not progressed as rapidly as might have been hoped since most research activities have been based on various types of shear testers intended to aid the design of hoppers. A new flowability indicator named as weighted cohesion (WS) is established using newly improved version of direct cohesion texture. A cornerstone of the proposed technique is that the procedure is automated, using a digital Warren Spring tester called Warren Spring-University of Malaya cohesion tester (WSUMCT), thus making results operator-insensitive. Besides being a practical tool to diagnose the cohesion of experimental powders, the ratio between measured cohesion (using WSUMCT) and aerated density (using Hosokawa PT-S) provides us with a powerful technique to research fundamental particle internal cohesion forces directly and use these data to indicate the flowability. In this work, a series of fine (9.4 μm) and coarse (60 μm) porous silica gel particle mixtures, and mixtures of fine (28 μm) and coarse (72 μm) glass ballotini as well, were used as test powders. The results from these tests agree well with relative flowability determined on our newly driven indicator using WSUMCT. The validation of aerated weighted cohesion (WSA) as a flowability indicator was authenticated by comparing the conducted parameter with established measured Hausner ratio (HR) and angle of repose (AoR).