- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

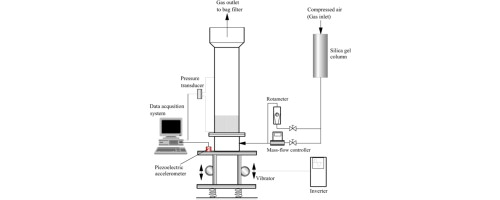

The fluidization behavior of nano and sub-micron powders belonging to group C of Geldart's classification was studied in a mechanically vibrated fluidized bed (vibro-fluidized bed) at room temperature. Pretreated air was used as the fluidizing gas whereas SiO2, Al2O3, TiO2, ZrSi, BaSO4 were solid particles. Mechanical vibration amplitudes were 0.1, 0.25, 0.35, 0.45 mm, while the frequencies were 5, 20, 30, 40 Hz to investigate the effects of frequency and amplitude of mechanical vibration on minimum fluidization velocity, bed pressure drop, bed expansion, and the agglomerate size and size distribution. A novel technique was employed to determine the apparent minimum fluidization velocity from pressure drop signals. Richardson–Zaki equation was employed as nano-particles showed fluid like behavior when fluidized. The average size of agglomerates formed on top of the bed was smaller than those at the bottom. Size distribution of agglomerates on top was also more uniform compared to those near the distributor. Larger agglomerates at the bottom of the bed formed a small fraction of the bed particles. Average size of submicron agglomerates decreased with increasing the frequency of vibration, however nano particles were less sensitive to change in vibration frequency. Mechanical vibration enhanced the quality of fluidization by reducing channeling and rat-holing phenomena caused by interparticle cohesive forces.