- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

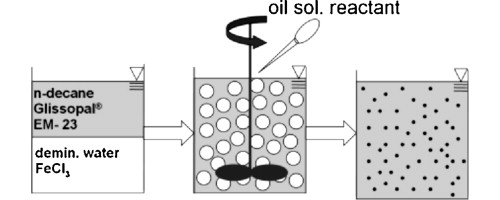

A method to precipitate nanoparticles using a miniemulsion technique is described, in which miniemulsion droplets between 100 and 1000 nm in size serve as nanoreactors enabling both the control of particle formation and particle growth. The application of miniemulsion droplets to synthesise nanoparticles comprises three advantages: first, the size of the precipitated particles is limited by the reactant concentration within the emulsion droplet; second, particle agglomeration is prevented as nanoparticle collision outside the nanoreactor is avoided; and third, easy technical scale up can be realized by increasing emulsion volume and thus the number of nanoreactors, while local conditions within the reactors are not changed. The miniemulsion technique is an easy scalable process which allows defined synthesis of particles by precipitation reactions. The miniemulsion technique involves first the preparation of a stable water-in-oil miniemulsion by high pressure homogenisation. Whereas a water soluble reactant is provided within the aqueous droplets, another oil- as well as water-soluble reactant can be introduced to the emulsion after homogenisation. The precipitation reaction is induced by the diffusion of the second reactant into the emulsion droplet. Together with this contribution, a method is described and discussed which uses a high pressure homogenisation process to produce stable water-in-oil miniemulsions serving as a reaction medium to precipitate metal oxides.