- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

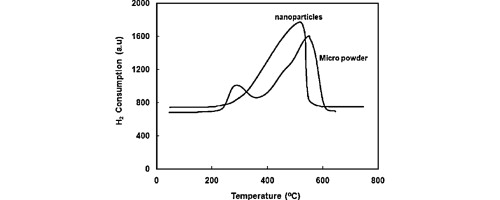

A simple and efficient method was developed for fabricating spherical granules of CuO catalyst via a three-step procedure. In the first step, copper oxide nanoparticles were synthesized by hydrothermal decomposition of copper nitrate solution under supercritical condition. Then, they were immobilized in the polymeric matrix of calcium alginate, and followed by high-temperature calcination in an air stream as the third step, in which carbonaceous materials were oxidized, to result in a pebble-type catalyst of high porosity. The produced CuO nanoparticles were characterized by transmission electron microscopy (TEM) that revealed an average size of 5 nm, X-ray diffractometry (XRD), and thermo gravimetric (TG) analysis. The catalysts were further investigated by BET test for measurement of their surface area, and by temperature-programmed reduction analysis (H2-TPR) for determination of catalytic activity. The results demonstrated that immobilization of the CuO nanoparticle in the polymeric matrix of calcium alginate, followed by calcination at elevated temperatures, could result in notable mechanical strength and enhanced catalytic activity due to preservation of the high surface area, both valuable for practical applications.