- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

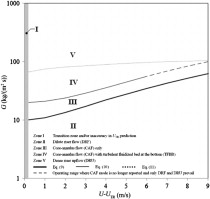

Riser operating modes are vital to designing a circulating fluidized bed (CFB) reactor for a required process of either a gas–solid or a gas–catalytic nature. Different operating modes provide different solids’ residence times and mixing behaviors, which define the reactions’ efficiency and yield. The literature demonstrates distinct operating modes resulting from observed differences in slip factors and the range of particle velocities and their associated residence time distribution. The present research uses positron emission particle tracking (PEPT) in a riser of B-type bed material to determine the different operating modes by measuring (i) particle velocities and residence time distribution, (ii) population densities of these particles in the cross-sectional area of the riser, and (iii) solids flow pattern at the bottom of the riser. Data treatment defines four distinct solids hold-up regimes in the riser and proposes a “phase diagram” depicting the existence of the different operating modes (dilute, dense, core-annulus and combined) as a function of the superficial gas velocity and solids circulation flux in the riser. The delineated regimes have good agreement with available literature data and known industrial operations. Comparison with literature data for risers using A-type powders is also fair. The diagram enables CFB designers to better delineate operating characteristics.