- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

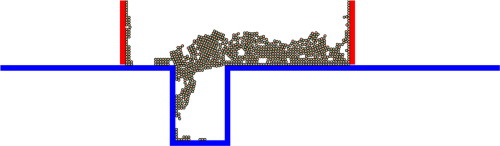

► Simulations of die filling with oppositely charged particles reveal that both fill ratio and critical filling speed generally decrease as electrostatic charge increases.

► When electrostatic charge is low, strong air/particle interaction results in lower fill ratio and lower critical filling speed as compared to those in a vacuum.

► When electrostatic charge is high, electrostatic interaction becomes dominant so that similar fill ratios and critical filling speeds are obtained both in air and in a vacuum.

The effects of electrostatic charge on powder flow behaviour during die filling in a vacuum and in air were analysed using a coupled discrete element method and computational fluid dynamics (DEM/CFD) code, in which long range electrostatic interactions were implemented. The present 2D simulations revealed that both electrostatic charge and the presence of air can affect the powder flow behaviour during die filling. It was found that the electrostatic charge inhibited the flow of powders into the die and induced a loose packing structure. At the same filling speed, increasing the electrostatic charge led to a decrease in the fill ratio which quantifies the volumetric occupancy of powder in the die. In addition, increasing the shoe speed caused a further decrease in the fill ratio, which was characterised using the concept of critical filling speed. When the electrostatic charge was low, the air/particle interaction was strong so that a lower critical filling speed was obtained for die filling in air than in a vacuum. With high electrostatic charge, the electrostatic interactions became dominant. Consequently, similar fill ratio and critical filling speed were obtained for die filling in air and in a vacuum.