- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

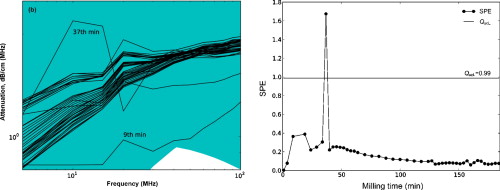

► Ultrasound attenuation spectroscopy (UAS) is used on-line for direct product quality control in nanomaterials processing.

► UAS raw spectra are used to derive multivariate statistical process control (MSPC) charts for monitoring nanoparticle quality.

► It avoids the difficulty associated with errors in estimating particle size distribution at high solid concentrations.

► The method is demonstrated using a wet milling process for size reduction of aluminum oxide particles.

Ultrasonic attenuation spectroscopy (UAS) is an attractive process analytical technology (PAT) for on-line real-time characterisation of slurries for particle size distribution (PSD) estimation. It is however only applicable to relatively low solid concentrations since existing instrument process models still cannot fully take into account the phenomena of particle–particle interaction and multiple scattering, leading to errors in PSD estimation. This paper investigates an alternative use of the raw attenuation spectra for direct multivariate statistical process control (MSPC). The UAS raw spectra were processed using principal component analysis. The selected principal components were used to derive two MSPC statistics, the Hotelling's T2 and square prediction error (SPE). The method is illustrated and demonstrated by reference to a wet milling process for processing nanoparticles.