- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

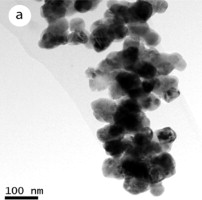

Zirconia (yttria)–alumina ceramic nanocomposites were fabricated from different powders by spark plasma sintering (SPS). One powder was a commercially available nanocomposite powder TZP-3Y20A, consisting of 3 mol% yttria-stabilized zirconia (3-YSZ) reinforced with 20 wt% alumina, and the other, used as a comparison, was a conventional mechanically mixed powder 3YSZ-20A, a blend made of 3 mol% yttria-stabilized zirconia powder ZrO2 (3Y) and 20 wt% α-alumina powder. The effect of the sintering temperature on the densification, the sintering behavior, the mechanical properties and the microstructure of the composites was investigated. The results showed that the density increased with increasing sintering temperature, and thus, the mechanical properties were strengthened because of the increased densification. The nanocomposite powder TZP-3Y20A was easily sintered, and good mechanical properties were achieved as compared with the powder from the conventional mechanically mixed method, the maximum flexural strength and fracture toughness of which were 967 MPa and 5.27 MPa m1/2, respectively.