- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

► The shear tests of different pulverized coals were investigated to obtain effect of powder properties and types on flow characteristics.

► Pulverized coals at high pressure were conveyed to study effect of operated parameters and powder properties on mass flow rate, solid–gas ratio and pressure drop.

► Results of conveying experiment and shear tests were linked to analyze the flow characteristics of pulverized coal.

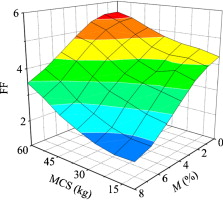

Experiments of dense-phase pneumatic conveying of pulverized coal using nitrogen were carried out in a test facility at pressures of up to 3.7 MPa to study the effects of coal type, particle size and moisture content on flow characteristics. The Jenike shear test and scanning electron microscopy (SEM) were employed to provide a better understanding of effects of the material properties on flow characteristics. Two kinds of pulverized coals, Yanzhou and Datong, with similar particle size, moisture content and density, were used in the test. Pressure drop increases with increasing the particle size at similar solid–gas ratio, superficial velocity and pressure in the receiving hopper, and pressure drops through different test sections decrease firstly and then rise with increasing the conveying velocity for the same particle size, mass flow rate and pressure in the receiving hopper. The flowability of pulverized coal decreases with increasing the moisture content in the range from 3.24% to 8.18%. Unconfined yield strength (UYS) increases and flow function (FF) decreases with increasing the moisture content. Results of the shearing tests are consistent with the results of the conveying study. Pressure drops through different test sections are discussed and analyzed.