- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

► Hydrodynamics of a gas–solid fluidized bed was studied via analyzing vibration signals measured by an accelerometer.

► The maximum value of Hurst exponent of macro structure occurred at the onset of regime transition from bubbling to turbulent.

► The results showed the methods are capable of detecting the regime transition from bubbling to turbulent fluidization using vibration signals.

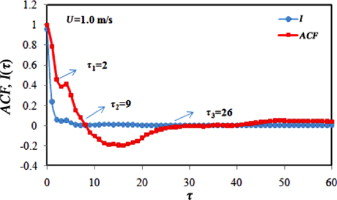

A non-intrusive vibration monitoring technique was used to study the hydrodynamics of a gas–solid fluidized bed. Experiments were carried out in a 15 cm diameter fluidized bed using 226, 470 and 700 μm sand particles at various gas velocities, covering both bubbling and turbulent regimes. Auto correlation function, mutual information function, Hurst exponent analysis and power spectral density function were used to analyze the fluidized bed hydrodynamics near the transition point from bubbling to turbulent fluidization regimes. The first pass of the autocorrelation function from one half and the time delay at which it becomes zero, and also the first minimum of the mutual information, occur at a higher time delay in comparison to stochastic systems, and the values of time delays were maximum at the bubbling to turbulent transition gas velocity. The maximum value of Hurst exponent of macro structure occurred at the onset of regime transition from bubbling to turbulent. Further increase in gas velocity after that regime transition velocity causes a decrease in the Hurst exponent of macro structure because of breakage of large bubbles to small ones. The results showed these methods are capable of detecting the regime transition from bubbling to turbulent fluidization conditions using vibration signals.