- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

► An activation index was introduced as a measure of particle surface hydrophobicity.

► According to activation index measurements and characterization of modified ADP powder, optimum modification conditions were determined as MHSO-to-ADP mass ratio 3%, exit air temperature below 100 °C and low humidity of inlet air for spray drying.

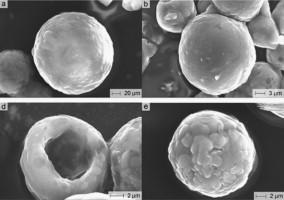

Superfine spherical fire-extinguishing powder, ammonium dihydrogen phosphate (ADP, NH4H2PO4), was prepared by spray drying and modified in situ with methyl hydrogen silicone oil (MHSO) emulsion and the fluorinated surfactant FK-510. The influences of the MHSO mass ratio on the hydrophobicity, surface composition, surface morphology, dispersion and particle-size distribution of the NH4H2PO4 were studied, and the influence of the drying air temperature on the decomposition of the NH4H2PO4 was also researched. The results indicate that the MHSO and FK-510 congregate on the particle surfaces and then form a hydrophobic shell. This shell improves the particle hydrophobicity and leads to a fine dispersion of the particles. During the process of preparing the precursor solution, 3 wt% (based on the weight of NH4H2PO4) was chosen as the optimum value of the MHSO mass ratio. During the spray drying, a low absolute humidity of the air should be maintained, and it is very important to keep the exit-air temperature below 100 °C to avoid decomposition.