- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

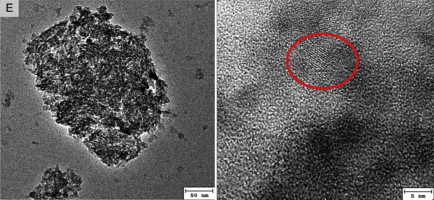

Co–Mo/γ-Al2O3–TiO2 hydrodesulfurization (HDS) catalyst samples prepared by a urea matrix combustion (UMxC) method, were evaluated in a stainless tubular fixed-bed reactor, with thiophene, benzothiophene and dibenzothiophene in xylene as model feedstocks. The samples were pre-sulfurized using a cyclohexane solution of 3% CS2 and then tested for the HDS reaction. The test results were compared with catalysts prepared by conventional methods involving sequential impregnation (SI) and co-impregnation (CI). The catalysts were characterized using X-ray diffraction (XRD), laser Raman spectroscopy (LRS), high resolution transmission electron microscopy (HRTEM) and N2 physisorption, showing that the UMxC catalyst had higher pore volume and surface area than those prepared by the CI and SI methods. The UMxC method increased metal loading and avoided formation of inert phase, e.g., β-CoMoO4, for the HDS reaction, suggesting that UMxC method is superior to the conventional impregnation techniques. TiO2 promoter made particles on the catalyst surface closer and alleviated the interaction between molybdenum oxide and the support, and facilitated the formation of well-dispersed Co- and Mo-oxo species on catalyst surface, thus resulting in higher HDS catalytic activity than pure γ-Al2O3 support without modifiers. Consequently, the addition of TiO2 obviously improved the HDS conversion of dibenzothiophene.