- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

► Superficial gas velocity has the most marked effect on granular temperatures including bubble, particle translational and particle rotational granular temperatures.

► Drag force model affects more seriously the large scale variables such as the bubble granular temperature.

► Simulation results are in reasonable agreement with experimental results.

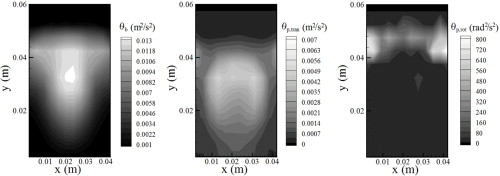

The discrete hard sphere particle model (DPM) is applied in this work to study numerically the distributions of particle and bubble granular temperatures in a bubbling fluidized bed. The dimensions of the bed and other parameters are set to correspond to those of Müller et al. (2008). Various drag models and operational parameters are investigated to find their influence on particle and bubble granular temperatures. Various inlet superficial gas velocities are used in this work to obtain their effect on flow characteristics. It is found that the superficial gas velocity has the most important effect on granular temperatures including bubble granular temperature, particle translational granular temperature and particle rotational granular temperature. The drag force model affects more seriously the large scale variables such as the bubble granular temperature. Restitution coefficient influences all granular temperatures to some degree. Simulation results are compared with experimental results by Müller et al. (2008) showing reasonable agreement.