- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

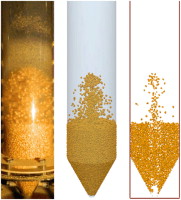

► Spouting of corn-shaped particles was simulated using a 3D CFD-DEM model with corn-shaped particles constructed by a multi-sphere method.

► The 4-spherical element construction showed smaller discrepancies between simulated and experimental results.

► Particle concentration increases in the spout region but decreases in the fountain region along the radial direction.

Three dimensionally coupled computational fluid dynamics (CFD) and discrete element method (DEM) were used to investigate the flow of corn-shaped particles in a cylindrical spouted bed with a conical base. The particle motion was modeled by the DEM, and the gas motion by the k-ɛ two-equation turbulent model. A two-way coupling numerical iterative scheme was used to incorporate the effects of gas–particle interactions in terms of momentum exchange. The corn-shaped particles were constructed by a multi-sphere method. Drag force, contact force, Saffman lift force, Magnus lift force, and gravitational force acting on each individual particle were considered in establishing the mathematical modeling. Calculations were carried out in a cylindrical spouted bed with an inside diameter of 200 mm, a height of 700 mm, and a conical base of 60°. Comparison of simulations with experiments showed the availability of the multi-sphere method in simulating spouting action with corn-shaped particles, but it depended strongly on the number and the arrangement of the spherical elements. Gas–solid flow patterns, pressure drop, particle velocity and particle concentration at various spouting gas velocity were discussed. The results showed that particle velocity reaches a maximum at the axis and then decreases gradually along the radial direction in the whole bed. Particle concentration increases along the radial direction in the spout region but decreases in the fountain region, while it is nearly constant in the annulus region. Increasing spouting gas velocity leads to larger pressure drop, remarkably increased speed of particle moving upward or downward, but decreased particle concentration.

Gas–solid flow; Discrete element method; Spouted bed; Corn-shaped particle; Multi-sphere method