- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

► A particle sub-model, describing the bed characteristics in terms of bed heights and particle distribution, is presented.

► Grey-box model is based on theoretical and empirical data from the literature and complemented with abstractions.

► Additional assumptions because information and data in the literature are sparse or non-existent.

► The model was capable of predicting the bed characteristics with good accuracy in less than 5 min calculation on a regular desktop PC.

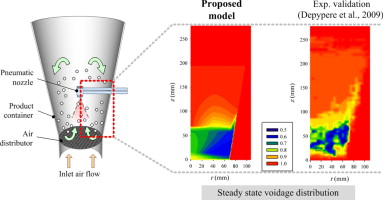

A particle sub-model describing the bed characteristics of a bubbling fluidised bed is presented. Atomisation air, applied at high pressures via a nozzle positioned above the bed for spray formation, is incorporated in the model since its presence has a profound influence on the bed characteristics, though the spray itself is not yet considered. A particle sub-model is developed using well-known empirical relations for particle drag force, bubble growth and velocity and particle distribution above the fluidised-bed surface. Simple but effective assumptions and abstractions were made concerning bubble distribution, particle ejection at the bed surface and the behaviour of atomisation air flow upon impacting the surface of a bubbling fluidised bed. The model was shown to be capable of predicting the fluidised bed characteristics in terms of bed heights, voidage distributions and solids volume fractions with good accuracy in less than 5 min of calculation time on a regular desktop PC. It is therefore suitable for incorporation into general process control models aimed at dynamic control for process efficiency and product quality in top-spray fluidised bed coating processes.