- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

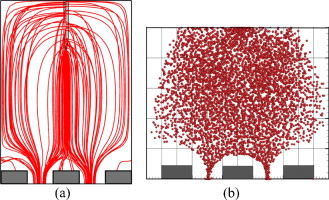

► Solution dielectric constant effect on electrospray deposition was simulated by Lagrangian model.

► Increasing solvent dielectric constant and applied voltage made spray area wider while no mask.

► Controlling focusing by changing surface charge density on mask was confirmed.

Electrospray deposition (ESD) as a patterning method of nanoparticles deposited on a substrate has attracted much attention due to several advantages over other methods. However, obtaining an optimum ESD processing condition for nanoparticle pattern relies much on trial experiments because of the lack of reliable numerical simulation. In this study, the deposition characteristics of nanoparticle generated by electrospray were investigated by using a three-dimensional Lagrangian model. Three important process parameters, including solution dielectric constant, applied voltage and surface charge density on mask were considered by fixing the geometrical parameters of the ESD device. Simulation result showed that under the condition of without a mask, the spray diameter increases with increasing solvent dielectric constant, and higher applied voltage makes the spray area wider. Controllability of focusing by changing surface charge density on the mask was confirmed: higher surface charge density on the mask results in more focused deposition. Validity of the numerical simulation developed in this study was verified by comparison with experimental data.