- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

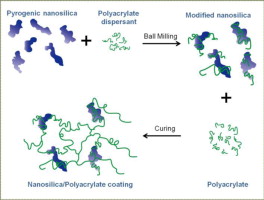

► A planetary ball milling was used to reduce the size of nanosilica agglomerates.

► Nanosilica/polyacrylate coating composites were prepared.

► Nanocomposites obtained exhibit good optical and mechanical properties.

The homogeneous dispersion of nanoparticles in solvents or polymer matrices is essential for practical application of nanocomposites. In this study, the planetary ball milling technique was used to de-agglomerate silica nanoparticles in butyl acetate. The size of the nanosilica aggregates was evaluated by TEM and SEM. With the addition of polyacrylate polymer to the organic solvent, the nanoparticle agglomerates were effectively broken up by planetary ball milling at the proper milling time; however, re-agglomeration occurred after a longer milling time. The results of TGA and FTIR indicated that the polyacrylate molecules could be adsorbed in situ onto the nanoparticles. Behaving similar to a dispersant, the adsorbed polyacrylate reduced the blend viscosity significantly and prevented re-agglomeration of the nanoparticles. Utilizing the polyacrylate polymer both as the dispersant and the polymer matrix, the polyacrylate-based nanocoatings were further prepared. The optical transmittance and haze value of the nanocoatings were found to be sensitive to the dispersion level of the nanoparticles, and the elastic modulus and hardness of the nanocoatings were improved in comparison with those of the neat polymer coating.