- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

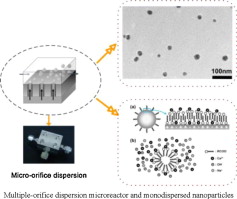

► In situ surface-modified CaCO3 nanoparticles were prepared in a microreactor.

► Particles prepared were highly hydrophobic and monodisperse with average size of 30 nm.

► Mechanism was speculated to explain surfactant effect in suspension system.

This study presents a novel process of in situ surface modification of CaCO3 nanoparticles using a multiple-orifice dispersion microreactor. CO2/Ca(OH)2 precipitation reaction was employed to prepare CaCO3 nanoparticles with sodium stearate surfactant. Synthesized CaCO3 products were characterized by thermogravimetric analysis (TGA), infra-red (IR), X-ray diffraction (XRD), transmission electron microscopy (TEM) and Brunauer–Emmet–Teller analysis (BET). The effect of various operation parameters on nanoparticles and the dosage of sodium stearate were determined. The results showed that the preparation process could be precisely controlled with efficient mass transfer process. The particles were highly hydrophobic with a contact angle of 117° and monodisperse with an average size of 30 nm. The adsorptions of sodium stearate and calcium ion on solid particles during the in situ surface modification process were investigated.