- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

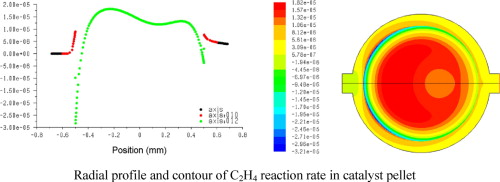

• Steady state behavior of OCM in a single catalyst pellet was studied by CFD.

• Diffusion, reaction and heat transfer were modeled in pellet scale.

• Simulation results were in reasonable agreement with experimental data.

• Results show that exothermic oxidation reactions occur before endothermic coupling reaction.

• At the forefront of the pellet reactions are dominant whereas at downstream diffusion predominates.

This study deals with the phenomena occuring at single-pellet catalyst scale for the oxidative coupling of methane where heat transfer plays an important role. Computational fluid dynamics (CFD) is used for obtaining detailed rate and temperature profiles through the porous catalytic pellet where reaction and diffusion compete. Intra-particle temperature and concentration gradients were taken into account by solving heat transfer coupled with continuity equations in the catalyst pellet. In heat transfer, the energy term due to highly exothermic reaction was considered. Two external programs were successfully implemented into the CFD-code as kinetic and heat of reaction terms. Simulation results showed that reaction was favored at the beginning for the pellet, followed by diffusion predomination. The results of CFD simulation indicate that temperature variation within the catalyst pellet is <2 K due to exothermic oxidation. The results showed further that exothermic oxidation reactions occurred prior to endothermic coupling reaction in the pellet.