- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

► Nano-CaCO3/PMMA CSNPs were synthesized by atomized microemulsion polymerization process.

► Polymer chains were anchored onto the surface of nano-CaCO3 through use of a coupling agent, TEVS.

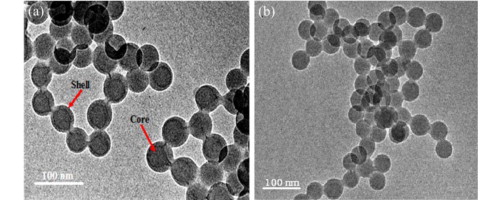

► Encapsulation of nano-CaCO3 by PMMA was confirmed by transmission electron microscopy.

► Inclusion of nano-CaCO3/PMMA core–shell particles in PP matrix resulted in reinforcement.

The synthesis of hard-core/soft-shell calcium carbonate (CaCO3)/poly(methyl methacrylate) (PMMA) hybrid structured nanoparticles (<100 nm) by an atomized microemulsion polymerization process is reported. The polymer chains were anchored onto the surface of nano-CaCO3 through use of a coupling agent, triethoxyvinyl silane (TEVS). Ammonium persulfate (APS), sodium dodecyl sulfate (SDS) and n-pentanol were used as the initiator, surfactant and cosurfactant, respectively. The polymerization mechanism of the core–shell latex particles is discussed. The encapsulation of nano-CaCO3 by PMMA was confirmed using a transmission electron microscope (TEM). The grafting percentage of the core–shell particles was investigated by thermogravimetric analysis (TGA). The nano-CaCO3/PMMA core–shell particles were characterized by Fourier transform infrared (FTIR) spectroscopy and differential scanning calorimetry (DSC). The FTIR results revealed the existence of a strong interaction at the interface of the nano-CaCO3 particle and the PMMA, which implies that the polymer chains were successfully grafted onto the surface of the nano-CaCO3 particles through the link of the coupling agent. In addition, the TGA and DSC results indicated an enhancement of the thermal stability of the core–shell materials compared with that of the pure nano-PMMA. The nano-CaCO3/PMMA particles were blended into a polypropylene (PP) matrix by melt processing. It can also be observed using scanning electron microscopy (SEM) that the PMMA chains grafted onto the CaCO3 nanoparticles interfere with the aggregation of CaCO3 in the polymer matrix (PP matrix) and thus improve the compatibility of the CaCO3 nanoparticles with the PP matrix.