- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

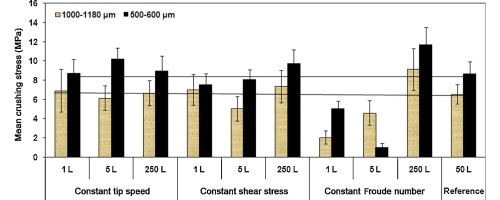

• Scale-up of a high shear granulator was studied.

• Granule properties and wall make-up were characterised as a function of granulator scale.

• Constant tip speed rule was found as the best criterion for scale-up of the granulator.

This study focuses on the characterisation of strength, density, and size of granules produced in various scales of a high shear granulator. Calcium carbonate (Durcal 65) was used as the feed powder and aqueous polyethylene glycol (PEG 4000) as the binder. The dried granules were analysed for their strength, density, size distribution, and wall make-up. Granules were produced in granulators with four scales, 1, 5, 50, and 250 L under three scale-up rules of constant tip speed, constant shear stress, and constant Froude number. The results show that regardless of equipment scale, increasing the impeller speed has a great effect on crushing strength and stress. The underlying cause is an increase in granule density due to more consolidation at higher impeller speeds. Wall make-up is significantly reduced to less than 5% as the scale is increased from 1 to 250 L. The results of this study corroborate our previous findings that the constant tip speed rule is the best criterion for scale-up of high shear granulators.