- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

Correlation of powder flow properties to interparticle interactions at ambient and high temperatures

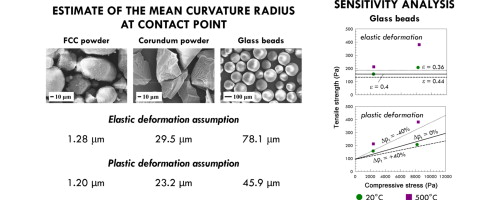

• Powder tensile strength is related to van der Waals interparticle forces.

• Rumpf equation is adopted.

• Elastic and plastic deformation at contact points is alternatively assumed.

• Plastic deformation and voidage decrease describe the effect of consolidation.

• Changes of the material strength can explain the effect of temperature.

A combination of a continuum approach and a particle–particle approach to describe the multi-scale nature of the mechanical properties of bulk solids may be beneficial to scientific and engineering applications. In this paper, a procedure is proposed to estimate the interparticle forces beginning with the bulk flow properties as measured with standardized techniques. In particular, the relationship between interparticle forces and bulk solid tensile strength is adopted based on the microscale approaches of Rumpf (1970) and Molerus (1975). The flow properties of fluid cracking catalyst (FCC), corundum and glass bead powders were all characterized with a modified Schulze ring shear cell capable of operating at temperatures up to 500 °C. The powder test conditions were selected such that the van der Waals forces were the most significant particle–particle interactions. The model equations describe two cases, in which either elastic or plastic deformation of the contact points is assumed. The results indicate that the model provides the correct order of magnitude for the values of the tensile strength when proper values for the mean curvature radius at the contact points are taken into account. A sensitivity analysis for the main parameters in the model was performed. This analysis indicated that the assumption of plastic deformation at contact surfaces coupled with a decrease in porosity justified an increase of the tensile strength with consolidation stress. Furthermore, the effect of temperature on the measured flow behavior can be explained as a change in the strength of the material.

Shear testing; Yield locus; van der Waals force; Interparticle interactions; Powder consolidation; High temperature