- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

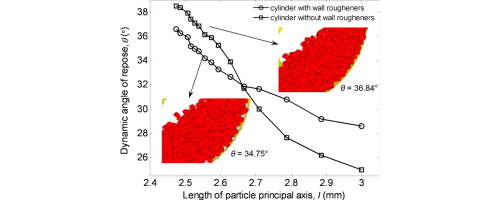

• Rotating cylinders containing non-spherical particles are modeled using the DEM.

• The influence of wall rougheners on the particle dynamics is investigated.

• Highly angular particles do not benefit from the inclusion of wall rougheners.

• The effect of wall rougheners depends on the operating condition of the granular bed.

Discrete-element-method (DEM) simulations have been performed to investigate the cross-sectional flow of non-spherical particles in horizontal rotating cylinders with and without wall rougheners. The non-spherical particles were modeled using the three-dimensional super-quadric equation. The influence of wall rougheners on flow behavior of grains was studied for increasing particle blockiness. Moreover, for approximately cubic particles (squareness parameters [5 5 5]), the rotational speed, gravitational acceleration and particle size were altered to investigate the effect of wall rougheners under a range of operating conditions. For spherical and near-spherical particles (approximately up to the squareness parameters [3 4 4]), wall rougheners are necessary to prevent slippage of the bed against the cylinder wall. For highly cubic particle geometries (squareness parameters larger than [3 4 4]), wall rougheners resulted in a counter-intuitive decrease in the angle of repose of the bed. In addition, wall rougheners employed in this study were demonstrated to have a higher impact on bed dynamics at higher rotational speeds and lower gravitational accelerations. Nevertheless, using wall rougheners had a comparatively small influence on particle-flow characteristics for a bed composed of finer grains.