- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• A granule consisting of 22,000 primary particles were modeled in 3D by DEM.

• Zeolite 4A granules were selected as the model material.

• Micro properties of the modeled granule are set so that the macro properties represent the zeolite granules.

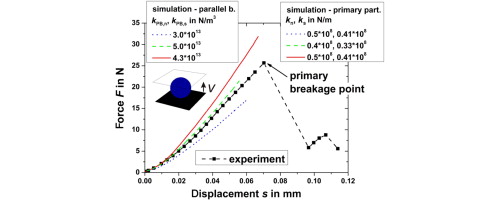

• Force–displacement curve of modeled granule was calibrated by experimental curve of zeolite.

The discrete element method (DEM), developed by Cundall and Strack (1979) to solve geomechanical problems, is used to simulate the mechanical behavior of granules. According to the DEM, an individual granule can be modeled as a realistic mechanical system consisting of primary particles bonded by interaction forces.

Granulometric properties of the model material, zeolite 4A, have been measured to determine their macro properties. To investigate the compression behavior, a compression test was performed using a strength tester on single granules between two pistons. A modeled granule consisting of more than 22,000 primary particles was generated. The micro properties of the modeled granule have been precisely set to allow its macro properties to be equivalent to the macro properties of zeolite 4A granules. To calibrate the mechanical properties, diametrical compression was simulated using two rigid walls stressed at a constant stressing velocity. The force–displacement curve of the modeled granule at compression has been calibrated by the experimental curve of zeolite 4A.