- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

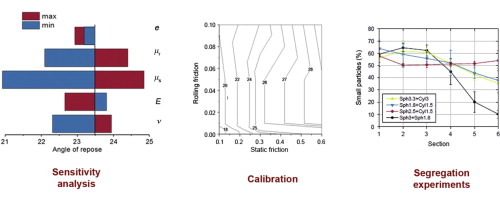

• DEM parameters were calibrated by comparing simulation results with experiments.

• DEM simulations and QPM segregation experiments show a good agreement.

• Particle size has a stronger effect than particle shape on segregation.

• Critical DEM parameters in segregation simulation are static and rolling friction.

Segregation of granular materials is a complex phenomenon, difficult to measure quantitatively and to predict. Discrete element method (DEM) can be a useful tool to predict segregation effects and to support the industrial design. In this context, a very challenging idea is the characterization of the granular solids to provide the key parameters needed for a successful DEM simulation of segregation processes. Rolling friction, sliding friction and the coefficient of restitution are the critical parameters to be studied. These microscopic simulation parameters are calibrated by comparing the macroscopic behavior of granular matter in standard bulk experiments, which have the advantage of being highly repeatable and reliable.

An experimental method is presented to characterize free surface segregation. The effects of different particle properties, particularly, shape and size, on segregation of cohesionless materials were investigated. From the experiments, particle size demonstrated a stronger effect on segregation than particle shape. Finally, the corresponding DEM simulations of the segregation experiments were presented. The parameters obtained by calibration were validated by the comparison of the modeled segregation behavior with the experimental results. Thus, calibrated DEM simulations are capable of predicting segregation effects.