- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

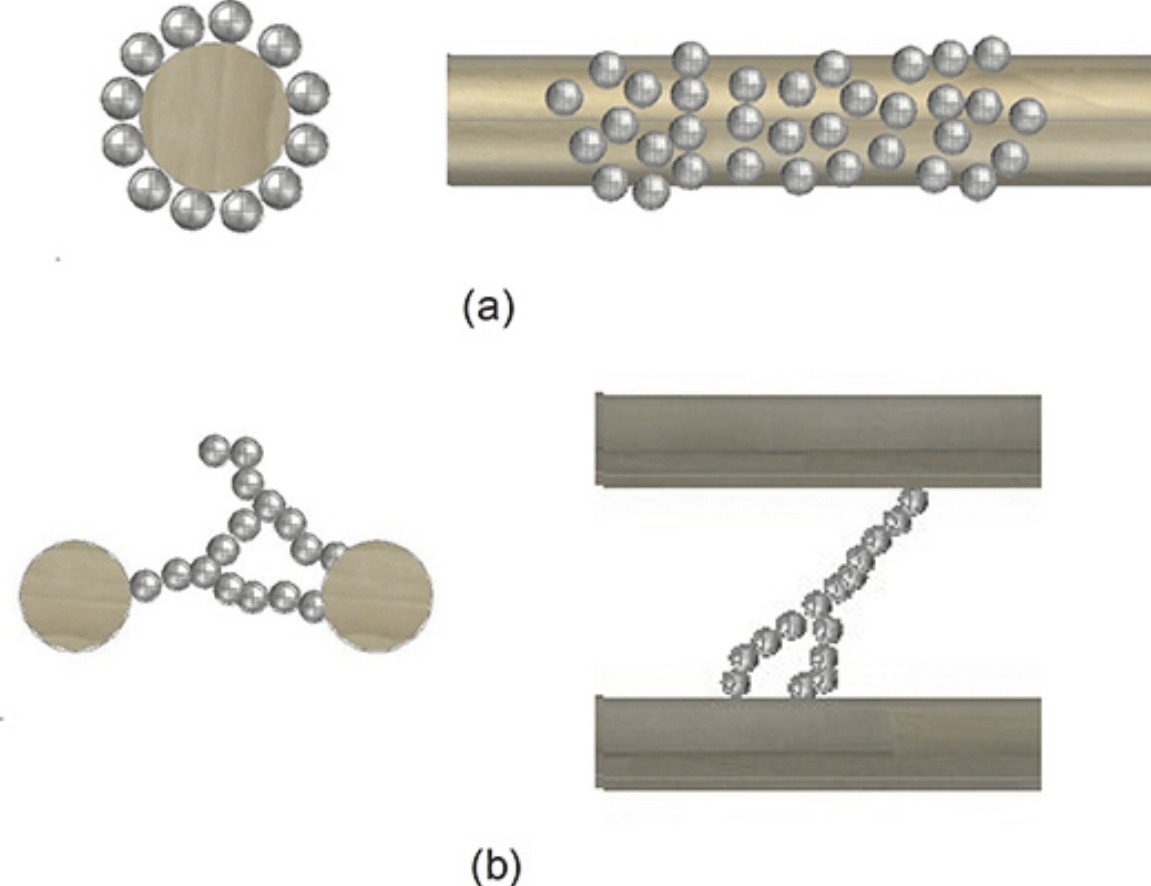

• Semi-analytical model of filtration performance for two particle deposit structures was developed.

• Dust loading effect on filtration performance was investigated via CFD simulation.

• Compact deposit structure slightly affected filtration efficiency and pressure drop.

• Dendritic deposit structure significantly affected filtration efficiency and pressure drop.

In this study, a semi-analytical model was developed to illustrate the relationship between filtration performance (filtration efficiency and pressure drop) and dust loading under two different particle deposit structures based on theoretical analysis and computational fluid dynamic (CFD) technology. Under the compact deposit structure, within the practical parameter ranges (fiber diameter, air velocity, dust loading mass), a slight efficiency enhancement (∼10%) occurred at the most penetration particle size (MPPS) and pressure drop increased significantly (∼100%) in response to the solidity increase from 5% to 15%. However, under the dendritic particle deposit structure, both filtration efficiency (∼40%) and pressure drop (∼600%) increased significantly with the same solidity increase due to the larger air velocity and swerve change between fibers.

Particle filtration; Deposition structure; Liquid droplet filtration; Filter dust loading