- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• Terbium oxide powder leakage from a micro-orifice of pressurize containers was investigated.

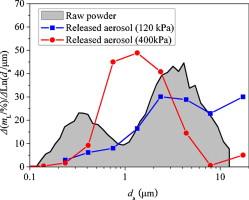

• Effects of orifice diameter, powder layer thickness and pressure on the leakage were studied.

• Orifice diameter has dominant effect on powder leakage amount.

Because of the radioactivity and toxic nature of nuclear materials, their containment within oxide matrices, encased in sealed containers, has been proposed as a suitable means for storage and transportation. However, container failures because of cracks or small orifices present a major leakage risk for nuclear materials, consequently posing a significant hazard to the environment and human beings. In this study, terbium oxide powder was used as a nuclear material representative to examine the leakage of nuclear material powder through orifices located at the base of a pressure container. The dependence of the orifice diameter, the powder layer thickness, and the internal pressure of the container on the leakage mechanism and amount was examined. A simplified model correlating the dependence of the above-mentioned parameters to determine the utmost leakage amount was also developed based on the present results. The leakage of the nuclear material powder was assessed by measuring its concentration using an optical particle counter. The diameter of the orifice determined the powder leakage mechanism, which in turn influenced the amount of leakage produced. Comparison studies showed that unlike the changes in the differential pressure, the volume of the container has little effect on the leakage amount. Under sufficiently high internal pressures, the oxide powder can be released as a fine aerosol. The work is not only crucial from the nuclear safety aspect, but is also beneficial for the safe application of powder and nanoparticles.