- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

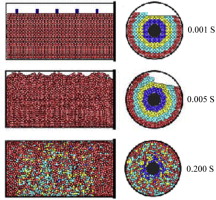

• Bead motion in a mill was simulated with DEM modified by enlarged particle model.

• Simulated velocity increases with increasing virtual frictional coefficient.

• Simulation data with optimum virtual frictional coefficient agree well with experimental results.

• The computing time in the simulation decreases using the modified DEM.

We applied the discrete element method (DEM) of simulation modified by an enlarged particle model to simulate bead motion in a large bead mill. The stainless-steel bead mill has inner diameter of 102 mm and mill length of 198 mm. The bead diameter and filling ratio were fixed respectively at 0.5 mm and 85%. The agitator rotational speed was changed from 1863 to 3261 rpm. The bead motion was monitored experimentally using a high-speed video camera through a transparent mill body. For the simulation, enlarged particle sizes were set as 3–6 mm in diameter. With the DEM modified by the enlarged particle model, the motion of enlarged particles in a mill was simulated. The velocity data of the simulated enlarged particles were compared with those obtained in the experiment. The simulated velocity of the enlarged particles depends on the virtual frictional coefficient in the DEM model. The optimized value of the virtual frictional coefficient can be determined by considering the accumulated mean value. Results show that the velocity of the enlarged particles simulated increases with an increase in the optimum virtual frictional coefficient, but the simulated velocity agrees well with that determined experimentally by optimizing the virtual frictional coefficient in the simulation. The computing time in the simulation decreases with increased particle size.