- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

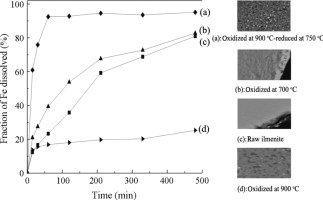

• Phase and structure changes during high-temperature oxidation and reduction were investigated.

• Influence of oxidation on leaching process is primarily attributed to the phase change.

• Reduction of as-oxidized ilmenite speeds up iron leaching due to microcracks and holes formation.

• The iron leaching rate is in the order of hematite > ilmenite ≫ pseudobrookite in hydrochloric acid.

The present study investigated the influence of high temperature oxidation and reduction pretreatments on the leaching rate of Panzhihua ilmenite. The as-pretreated ilmenite was leached with 20% HCl at 105 °C. The leaching process was controlled by the phases and microstructures that evolved during the pretreatment processes. The leaching kinetics of pure hematite, ilmenite and pseudobrookite were characterized to clarify the phase effect on the iron-leaching rate; the rate of iron leaching occurs in the following order in the HCl solution: hematite (ferric iron) > ilmenite (ferrous iron) ≫ pseudobrookite (ferric iron). Therefore, the often-cited notion that ferrous iron dissolves faster in HCl solutions than ferric iron when explaining the pretreatment effects is inaccurate. Moreover, the oxidation pretreatment (at 600–1000 °C for 4 h) cannot destroy the dense structure of the Panzhihua ilmenite. Therefore, the influence exerted by the oxidation on the leaching process is primarily determined by the phase change; oxidation at 600 and 700 °C slightly increased the rate of iron leaching because the ilmenite was transformed into hematite, while the oxidation at 900–1000 °C significantly reduced the rate of iron leaching because a pseudobrookite phase formed. The reduction effect was subsequently investigated; the as-oxidized ilmenite was reduced under H2 at 750 °C for 30 min. The reduction significantly accelerated the rate of subsequent iron leaching such that nearly all of the iron had dissolved after leaching for 2 h in 20% HCl at 105 °C. This enhanced iron-leaching rate is mainly attributed to the cracks and holes that formed during the reduction process.