- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• A fluid dynamic model for a gas–solid CFB consisting of two coupled riser reactors is developed.

• The model represents a step further in complexity from the conventional Kunii-Levenspiel type of models.

• Based on this model simulations reproduced the relevant experimental data in the literature.

• Simulation shows that sufficient heat integration between the two reactor units is very important.

• The model performs fairly well for the chemical loop process in question.

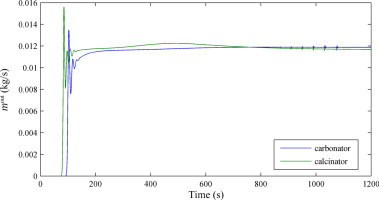

A fluid dynamic model for a gas-solid circulating fluidized bed (CFB) designed using two coupled riser reactors is developed and implemented numerically with code programmed in Matlab. The fluid dynamic model contains heat and species mass balances to calculate temperatures and compositions for a carbonation/calcination loop process.

Because of the high computational costs required to resolve the three-dimensional phenomena, a model representing a trade-off between computational time requirements and accuracy is developed. For dynamic processes with a solid flux between the two reactor units that depends on the fluid dynamics of both risers, a dynamic one-dimensional two-fluid model is sufficient.

A two-fluid model using the constant particle viscosity closure for the stress term is used for the solid phase, and an algebraic turbulence model is applied to the gas phase. The numerical model implementation is based on the finite volume method with a staggered grid scheme. The exchange of solids between the reactor units constituting the circulating fluidized bed (solid flux) is implemented through additional mass source/sink terms in the continuity equations of the two phases.

For model validation, a relevant experimental analysis provided in the literature is reproduced by the numerical simulations. The numerical analysis indicates that sufficient heat integration between the two reactor units is important for the performance of the circulating fluidized bed system.

The two-fluid model performs fairly well for this chemical process operated in a CFB designed as two coupled riser reactors. Further analysis and optimization of the solution algorithms and the reactor coupling strategy is warranted.