- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• Straight pipe PCC showed gradual variation of pressure with mass flow rate of air.

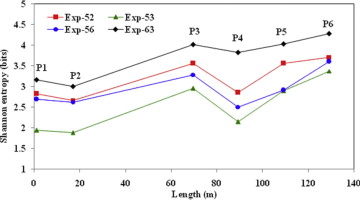

• Pressure fluctuations were investigated using standard deviation and Shannon entropy.

• Shannon entropy and standard deviation values tended to decrease after flow through bend(s).

• Shannon entropy variation along the pipeline length provided insight into change in flow.

• Flow turbulence increases along the length of pipeline.

This paper presents the results of an ongoing investigation into the fluctuations of pressure signals due to solids–gas flows for dense-phase pneumatic conveying of fine powders. Pressure signals were obtained from pressure transducers installed along different locations of a pipeline for the fluidized dense-phase pneumatic conveying of fly ash (median particle diameter 30 μm; particle density 2300 kg/m3; loose-poured bulk density 700 kg/m3) and white powder (median particle diameter 55 μm; particle density 1600 kg/m3; loose-poured bulk density 620 kg/m3) from dilute to fluidized dense-phase. Standard deviation and Shannon entropy were employed to investigate the pressure signal fluctuations. It was found that there is an increase in the values of Shannon entropy and standard deviation for both of the products along the flow direction through the straight pipe sections. However, both the Shannon entropy and standard deviation values tend to decrease after the flow through bend(s). This result could be attributed to the deceleration of particles while flowing through the bends, resulting in dampened particle fluctuation and turbulence. Lower values of Shannon entropy in the early parts of the pipeline could be due to the non-suspension nature of flow (dense-phase), i.e., there is a higher probability that the particles are concentrated toward the bottom of pipe, compared with dilute-phase or suspension flow (high velocity), where the particles could be expected to be distributed homogenously throughout the pipe bore (as the flow is in suspension). Changes in straight-pipe pneumatic conveying characteristics along the flow direction also indicate a change in the flow regime along the flow.

Fluidized dense-phase; Pneumatic conveying; Fine powders; Shannon entropy; Flow transition; Particle turbulence