- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

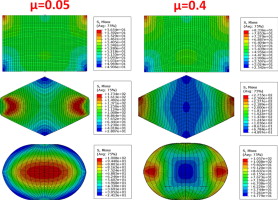

• The calibration procedure of Drucker–Prager cap model was discussed for powder compaction.

• Mechanical behavior of powder during compaction was modeled using FEM together with DPC model.

• Influences of punch shape and wall friction on powder compaction were investigated.

During the production of pharmaceutical tablets using powder compaction, certain common problems can occur, such as sticking, tearing, cutting, and lamination. In the past, the compressibility of the powder was calculated only along the axis of the device; consequently, critical areas of the material throughout the volume could not be identified. Therefore, finite element method (FEM) can be used to predict these defects in conjunction with the use of an appropriate constitutive model. This article summarizes the current research in the field of powder compaction, describes the Drucker–Prager Cap model calibration procedure and its implementation in FEM, and also examines the mechanical behavior of powder during compaction. In addition, the mechanical behavior of pharmaceutical powders in relation to changes in friction at the wall of the system is examined, and the dependence of lubrication effect on the geometry of the compaction space is also investigated. The influence of friction on the compaction process for the flat-face, flat-face radius edge, and standard convex tablets is examined while highlighting how the effects of friction change depending on the shape of these tablets.