- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• Effects of particle intrinsic parameters on milling performance were investigated using DEM.

• As elastic modulus and particle sliding friction increase the dissipated energy increases.

• At a given collision frequency the normal energy dissipation is higher.

• Increase in fraction of mill critical speed increases the mill power draw.

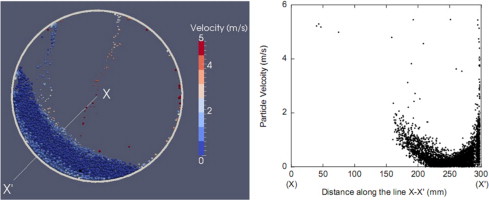

Discrete element method (DEM) has been used to investigate the effects of particle elastic modulus and coefficient of inter-particle sliding friction on milling of mineral particles. An autogeneous mill of 600 mm diameter and 320 mm length with 14,500 particles has been selected for the simulation. Various mill performance parameters, for example, particle trajectories, collision frequency, collision energy and mill power have been evaluated to understand the effects of particle elastic modulus and inter-particle sliding friction during milling of particles.

For the given model, it has been concluded that at high energy range, as the elastic modulus and particle sliding friction increase the energy dissipated among the particles increases. The collision frequency increases with the increase in elastic modulus, however, this trend is not clearly observed with increasing inter-particle sliding friction. The power draw of the mill increases with the increase in fraction of mill critical speed.