- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

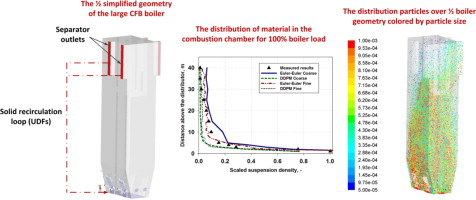

• Application of a hybrid Euler–Lagrange approach for a large scale CFB facility was shown.

• Air-fuel combustion process was modeled for a large scale industrial CFB boiler.

• Numerical simulation results were validated against experimentally measured data.

The constantly developing fluidized combustion technology has become competitive with a conventional pulverized coal (PC) combustion. Circulating fluidized bed (CFB) boilers can be a good alternative to PC boilers due to their robustness and lower sensitivity to the fuel quality. However, appropriate engineering tools that can be used to model and optimize the construction and operating parameters of a CFB boiler still require development. This paper presents the application of a relatively novel hybrid Euler–Lagrange approach to model the dense gas–solid flow combined with a combustion process in a large-scale industrial CFB boiler. In this work, this complex flow has been resolved by applying the ANSYS FLUENT 14.0 commercial computational fluid dynamics (CFD) code. To accurately resolve the multiphase flow, the original CFD code has been extended by additional user-defined functions. These functions were used to control the boiler mass load, particle recirculation process (simplified boiler geometry), and interphase hydrodynamic properties. This work was split into two parts. In the first part, which is referred to as pseudo combustion, the combustion process was not directly simulated. Instead, the effect of the chemical reactions was simulated by modifying the density of the continuous phase so that it corresponded to the mean temperature and composition of the flue gases. In this stage, the particle transport was simulated using the standard Euler–Euler and novel hybrid Euler–Lagrange approaches. The obtained results were compared against measured data, and both models were compared to each other. In the second part, the numerical model was enhanced by including the chemistry and physics of combustion. To the best of the authors’ knowledge, the use of the hybrid Euler–Lagrange approach to model combustion is a new engineering application of this model. In this work, the combustion process was modeled for air-fuel combustion. The simulation results were compared with experimental data. The performed numerical simulations showed the applicability of the hybrid dense discrete phase model approach to model the combustion process in large-scale industrial CFB boilers.