- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

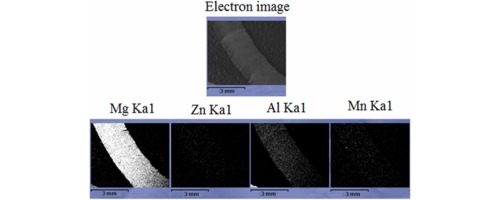

• Waste Mg chips (WMCs) were characterized in terms of potential use as a hydrogen storage medium.

• Mechanical milling, tetrahydrofuran and NaCl treatment were applied to modify the WMC surface.

• The obtained Mg-rich intermetallic composite exhibited a hydrogen storage capacity of 4.59 wt%.

In this study, the characterization and modification of waste magnesium chips (WMCs), which were produced by plastic molding in a gold manufacturing factory and are used as Mg-rich intermetallic composites in storing hydrogen, were discussed in detail. WMCs were analyzed using X-ray diffraction (XRD), X-ray fluorescence (XRF) spectroscopy, differential scanning calorimetry (DSC), scanning electron microscopy (SEM), and Brunauer–Emmett–Teller (BET) analysis to characterize the materials’ structural properties. Mechanical milling, organic treatment, and inorganic salt addition were carried out to modify the WMCs’ surface to prepare Mg-rich intermetallic composites for storing hydrogen. The modified samples were analyzed using high-pressure volumetric analyses to calculate their hydrogen storage capacity. The authors conclude that modified WMC was promising as an Mg-rich intermetallic composite that was suitable for use in hydrogen storage with a 4.59 wt% capacity at 320 °C under a hydrogen pressure of 60 bar.