- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

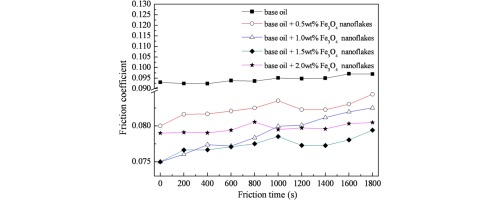

• Friction coefficient with base oil of 1.5 wt% Fe3O4 nanoflakes decreased by 18.06%.

• After 48-h friction, chemical composition of the base oil did not change.

• During friction, Fe3O4 particle size decreased due to lattice distortion.

• Formation of tribochemical film on friction surface may improve the friction properties.

This detailed the tribological and tribochemical properties of magnetite (Fe3O4) nanoflakes used as additives in #40 base oil in a four-ball tribo-tester. The average friction coefficient of the friction pair for lubricant containing the Fe3O4 nanoflakes of 1.5 wt% as a lubricant additive in the base oil is decreased by 18.06% compared to that of solely base oil. The chemical composition of base oil with the Fe3O4 nanoflake additives did not change during the 48-h friction assessment. The decreased saturation magnetization and increased coercivity of magnetite nanoflakes occurred due to the distortion of the basal planes and the presence of hematite (α-Fe2O3) generated by the tribochemical reactions during the friction process. The multi-layer low-shear-stress tribochemical lubrication films on the surface of the friction pair could form because the nanoflake particles arrange and adhere onto the surface of the friction pair in an orderly manner, and the tribochemical reactions of the friction pair in the presence of the nanoflakes occur as Fe → FeO → Fe3O4 → γ-FeOOH → γ-Fe2O3 → α-Fe2O3. The formation of the films can improve the tribological properties.