- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

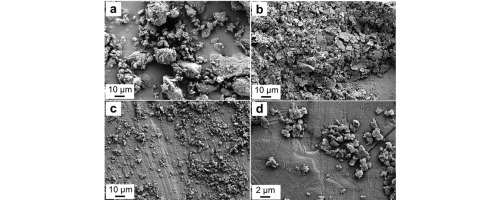

• Poly(amide imide) powder was wet-milled in an attritor at various milling conditions.

• Polymer powder median diameter was reduced from 21 to 3 μm after 7-h milling.

• After milling the as-received suspension was stable.

The milling behavior of poly(amide imide), which serves as a prototypical hydrophilic high-performance polymer with a high glass transition temperature, was investigated. Various milling conditions (milling times up to 7 h, stirrer tip speeds of 3.4–4.9 m/s, and mass concentrations of 5–20%) were tested, and particle sizes as low as d50,3 ∼ 3 μm were obtained. The milling was performed at 11 °C in an attritor. Differential scanning calorimetry and thermogravimetric analysis were performed before and after milling to investigate the effect of milling on the glass transition temperature and on the decomposition behavior of the polymer. The suspension obtained after milling was observed to be stable without the addition of stabilizers or the adjustment of the pH value, and no negative effect of milling on the polymer properties was observed. The attritor technique proved to be an adequate and efficient milling tool for the production of micrometer-sized high-performance polymer suspensions.