- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

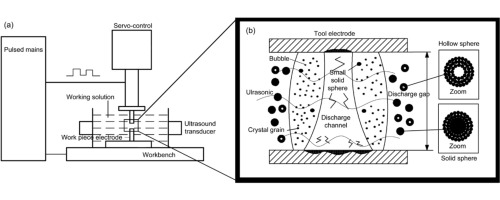

• Hollow nickel microspheres were produced by ultrasound-aided electric discharge machining method.

• EDM machine used kerosene as dielectric medium, nickel strips as electrodes at 40 kHz ultrasounds.

• Short pulse widths, low voltages, and low currents favored formation of smaller microspheres.

Ultrasound-aided electric discharge machining (EDM) is an emerging technology for producing hollow nickel microspheres. This technology combines traditional EDM with the cavitation and vibration effects of ultrasound to produce hollow microspheres. In this paper, ultrasound-aided EDM was carried out in a kerosene medium (the working solution). The effects of various parameters on the sizes of microspheres were investigated using scanning electronic microscopy (SEM). Smileview software was used to measure the sizes of the microspheres. Originpro software was used for statistical analysis to determine the size distributions of the microspheres. To study the effects of the system parameters on the sizes of the microspheres, we first investigated the necessity of using an ultrasonic wave with EDM. After comparing the experimental results with and without the ultrasonic field, we found that ultrasound-induced cavitation and vibration effects reduced the diameters of the microspheres. We then studied the effects of several electrical parameters, including the arc current, pulse width, and gap voltage, on the sizes of the microspheres at an ultrasound frequency of 40 kHz. Smaller microspheres could be obtained by lowering the arc current, pulse width, and gap voltage.