- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• N2 bypass through the chute between FFB and BFB in a dual fluidized bed gasifier was studied.

• The effect of fluidizing velocity on the hydrodynamics of the DFBG and DFCM was investigated.

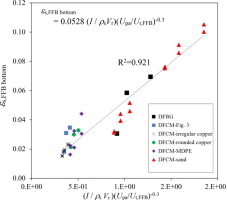

• Correlations for height-averaged solid fraction in the bottom of FFB and BFB were developed.

• The correlations are useful for potential industry applications.

Dual fluidized bed gasifiers (DFBG) are effective in producing nitrogen-free syngas from biomass. However, to improve the gasifier performance, pressure drops and solid fractions within the DFBG system need to be controlled. In this study, the effects of varying the fluidizing velocity in the fast fluidized bed (FFB) on the pressure drops and the solid fractions in the system were investigated in a 100 kW DFBG and in a dual fluidized bed cold model (DFCM). Based on the experimental results, empirical correlations were developed to predict the height-averaged solid fraction in the bottom section of the FFB. Accuracy and advantages of the correlations were analyzed. The correlation is useful for design and modeling of the DFBG systems where the height-averaged solid fraction is required to be determined.