- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

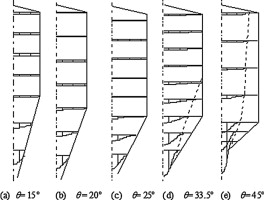

• An in-house finite element program was used to predict solids flow patterns in silos.

• Upper lateral pressure ratio determined the critical hopper half angle.

• Size and shape of stagnant zone in funnel flow silos were predicted.

• The calculated results showed that placing a double-cone insert could change solid flow patterns.

• Verifications were carried out to check parts of the predicted results using published results.

Obtaining a reliable discharge of particulate solids from a storage silo is a prerequisite to securing operational adequacy in solids handling processes. If a silo is poorly designed, an unreliable interrupted discharge often occurs. In this study, an in-house finite element (FE) program was modified to predict the particulate solids flow patterns during discharges from silos, and the effect of a double-cone insert on such flow patterns. In FE modeling, a Eulerian approach was adopted with an assumption of steady-state flow—a state that greatly facilitated investigations on the effects of double-cone inserts on the flow of particulate solids. Predictions were carried out on whether the discharge was in mass flow or funnel flow, associated with the inclination angle of the silo's hopper. Predicted results were in agreement with the Jenike Chart, and proved that an upper lateral pressure ratio value gave a better critical hopper half angle to achieve mass flow (EN 1991-4, 2006). The shape and size of the stagnant zone were further discussed to address the flow channel boundary between the flowing and static solids if the discharge was in a funnel pattern. Results also showed the effects of a double-cone insert on the flow patterns which converted silos from funnel flow to mass flow up to a certain hopper inclination angle and would improve the flow pattern even for shallower angles. Experiments were carried out to verify some of the predicted results. Some qualitative comparisons were made between the predicted results and experimental measurements, which indicated that further efforts are needed in predicting the shape of the stagnant zone (flow channel boundary) during funnel flow discharges.