- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

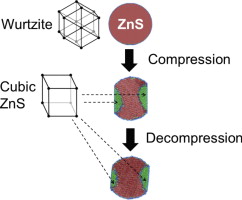

• MD simulations predict transformation of wurtzite to cubic ZnS by compression.

• Powder compression and wet milling experiments agree well with MD simulations.

• Stress number governs degree of phase transformation and defect formation.

• Mechanically induced microstructural changes lower photoluminescence of ZnS.

Molecular dynamics (MD) simulations of the consecutive compression–decompression cycles of hexagonal zinc sulfide (wurtzite) nanoparticles predict an irreversible phase transformation to the cubic polymorph. The phase transformation commences at the contact area between the particle and the indenter and proceeds with the number of compression cycles. Dislocations are visible for a particle size above 5 nm.

Results from wet grinding and dry powder compression experiments on a commercial wurtzite pigment agree qualitatively with MD simulation predictions. X-ray diffraction patterns reveal that the amount of cubic polymorph in the compressed samples increases with pressure applied to the powder. In comparison with powder compression, wet milling leads to a more pronounced phase transformation. This occurs because the particles are exposed to a large number of stress events by collision with the grinding media, which leads to the formation of defects and new surface crystallites by particle fracture. According to the MD simulations, phase transformation is expected to occur preferentially in surface crystallites because they experience the highest mechanical load.

Because of the phase transformation, the wet ground and compressed samples exhibit a lower photoluminescence intensity than the feed material. In comparison with powder compression, milling reduces the photoluminescence intensity more substantially. This occurs because a higher defect concentration is formed. The defects contribute to the phase transformation and photoluminescence quenching.