- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

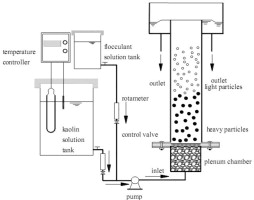

• Multi-stage velocity gradients were set up in a cylindrical fluidized bed.

• Multi-stage velocity gradients fluidized bed (MGF) was beneficial to protection of flocs.

• The required velocity gradients could be achieved by formulating solid phase.

• Suspended solids and dispersed dyes could be removed more efficiently in MGF.

Flocculation time is conventionally believed to be proportional to the flocculation efficiency of a cylindrical fluidized bed flocculator. However, in a single-stage velocity gradient situation, the flocculation efficiency decreases when the optimal flocculation time is exceeded. A multi-stage velocity gradient was established in a cylindrical fluidized bed flocculator, based on the hydraulic classification theory. This multi-stage velocity gradient fluidized bed flocculator (MGF) created a more suitable environment for floc growth and protection, which was confirmed by the size distribution of flocs along the bed height. Correspondingly, the abatement efficiencies for Kaolin slurry and dyed wastewater treatment in the MGF were enhanced by 5–10%, and by 7–20%, respectively, compared with those in the single-stage velocity gradient fluidized bed flocculators (SGFs). The initial bed height distribution ratio along the velocity gradients was an important factor for MGF optimization.