- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

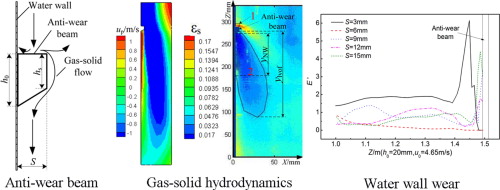

• An anti-wear mechanism of an anti-wear beam on the water wall was proposed for the first time.

• Upward moving solids were observed and simulated in a certain area below an anti-wear beam.

• An optimum beam width was suggested in the test rig for the least wear rate.

Anti-wear beams installed on water walls of circulating fluidized bed (CFB) boilers are one of the most effective ways to protect against water-wall erosion. Beam effects from, for example, beam size and superficial gas velocity were investigated on gas–solid hydrodynamics in a CFB test rig using CFD simulations and experimental methods. The downward flow of the wall layer solids is observed to be disrupted by the beam but is then restored some distance further downstream. When falling solids from the wall layer hit the anti-wear beam, the velocity of the falling solids decreases rapidly. A fraction of the solids accumulates on the beam. Below the beams, the falling solids have reduced velocities but upward-moving solids were observed on the wall. The effect of the beam increases with width and superficial gas velocity. Wear occurs mainly above the beam and its variation with width is different above to below the beam. There is an optimum width that, when combined with beam height, results in less erosion.