- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

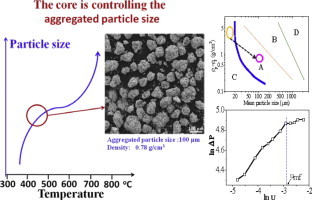

• High purity and low density ultrafine nickel powder was prepared by a two-stage reduction process.

• Formation of agglomerated Ni particles at lower temperatures was crucial to avoiding defluidization.

• A concept design of a two-stage fluidized bed reactor process was proposed for Ni production.

• This method may be extended to synthesis of other nanoparticles.

A novel two-stage reduction process for synthesis of ultrafine nickel powder with a high purity and low density in a fluidized bed reactor has been developed in this work. The raw ultrafine NiO particles are first pre-reduced using hydrogen at lower temperatures (340–400 °C), followed by further reduction at higher temperatures (500–600 °C). The self-agglomeration of Ni particles formed during low-temperature reduction decreases the sintering activity of the newly formed ultrafine Ni particles, leading to good fluidization quality, even for the subsequent high-temperature reduction process. The agglomerated Ni particles have a high Ni content (above 99 wt%), a low density (0.78 g/cm3) and a uniform particle size (approximately 100 μm). A concept design for a novel two-stage fluidized bed reactor process used to produce high-purity Ni powder was also proposed. This approach may be extended to the synthesis of other ultrafine/nanosized metals or metal oxides through a fluidization method.