- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

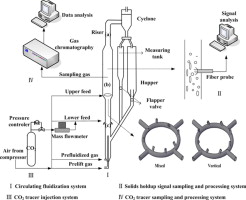

• Fast-turbulent fluidized bed (FTFB) riser with expanding section and ring-feeder was investigated.

• Two types of ring-feeder (mixed and vortex) were used to improve gas–solid contact efficiency.

• Two probability peaks of solid fraction signals existed in FTFB riser with vortex ring-feeder.

• Ring-feeder structure affected flow dynamics and gas–solid contact efficiency in FTFB risers.

The flow dynamics in a novel fast-turbulent fluidized bed (FTFB) with middle-upper expanding structure and two different ring-feeder internals (mixed and vortex ring-feeder) were studied to achieve a reduction in gasoline olefin production. Compared with a conventional circulating fluidized bed, the novel FTFB displayed unique characteristics and advantages. A higher solids holdup and more uniform solids holdup distribution existed in the diameter-expanding region, especially for the FTFB with vortex ring-feeder structure. A probability density distribution analysis indicated that the novel fluidized bed could reduce gas–solids segregation and enhance gas–solids interaction. A constant carbon dioxide tracer system was used to simulate the reactant gas distribution. The gas–solids contact efficiency was defined according to the solid dispersibility and the amount of gas covering the solid surface. Novel FTFB risers, especially those with vortex ring-feeders, have a much higher gas–solids contact efficiency than that of traditional risers.